We think ecologically

We are Hyundai Motor Manufacturing Czech, and we care about the impact our production has on the environment. Our commitment to ecological principles is not just words, but concrete actions that focus on real change. Take a look at how our daily activities contribute to environmental protection.

Cleaner Air and Lower Emissions

To improve air quality, we have implemented Regenerative Thermal Oxidation (RTO) technology, which effectively reduces volatile organic compound (VOC) emissions from production. With an efficiency of over 97%, RTO allows us to meet even the strictest limits, even with higher production volumes. We safely comply with the VOC emission limit of 350 tons per year.

We are also focused on reducing CO₂ emissions. The average emissions over the last 5 years at HMMC are 105.1 kg of CO₂ per vehicle. Our goal for 2025 is to reduce this value to 99 kg of CO₂ per vehicle – a step that will bring us closer to our carbon neutrality strategy.

We Recycle

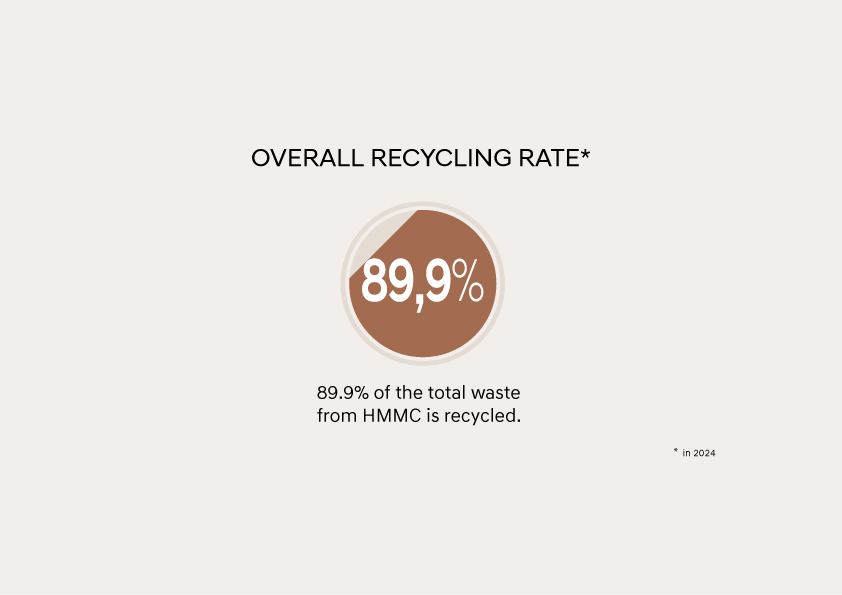

Recycling is a fundamental part of our responsible approach to waste management. In 2024, we successfully recycled 89.9% of all waste, which amounts to 46,118 tons of material that did not end up in a landfill. Our goal is to continue increasing this percentage.

Through consistent waste sorting and processing, we save natural resources while reducing our ecological footprint. Over the past five years, we have generated an average of 164 kg of waste per vehicle produced.

Reducing Material Consumption

Our production processes are designed to conserve materials and minimize waste as much as possible. We use water-based paints with low volatile organic compound (VOC) content, significantly reducing emissions during manufacturing. By optimizing paint usage, we’re able to further cut down on VOCs. Thanks to these measures, we plan to save approximately 170 tons of paint and solvents.

We also proudly support upcycling — discarded car parts are transformed into unique items available for purchase in our H.Shop.

Supporting Biodiversity and Local Communities

As part of our commitment to environmental responsibility, we actively participate in biodiversity protection projects. In 2024, we planted 56 trees and shrubs on our premises and financially supported a project for the restoration of natural ecosystems in our region. Additionally, our employees regularly take part in volunteer days, during which they help improve the local environment.

In 2024, in collaboration with ČSOP Salamandr, we also conducted a biodiversity study at the HMMC site. As part of the botanical survey, we recorded 136 plant species, the highest number historically in the monitoring process. Among them are 41 species of mosses, 2 species of horsetails, 1 species of ferns, and 92 species of seed plants. The increase of 2 species compared to 2023 shows that biodiversity at our site is growing.

We Are Energy Efficient

We are constantly working to optimize our manufacturing processes to save energy and minimize our carbon footprint. We use modern technologies such as regulated lighting and other sophisticated systems that help us reduce energy consumption. In 2024, we installed 1,940 new LED lights, resulting in an energy saving of 371 MWh.

In addition, we are conserving water. Since 2020, we have been continuously reducing the amount of water used per car produced. In 2024, water consumption was 1.14 m³ per car produced, compared to 1.25 m³ in 2023.

Certifications and Awards

Our facilities are certified according to international standards ISO 14001 and EMAS. These certifications confirm that we approach environmental management systematically and are committed to continuously improving our environmental performance.

For our efforts, we have been repeatedly recognized. For example, we received the Moravian-Silesian Region Governor’s Award for responsible projects in Corporate Social Responsibility (CSR).

Electromobility and Clean Energy

We are investing in the development and production of electric vehicles, which represent a key step towards cleaner and more sustainable transportation. The KONA Electric, which we have been producing in Nošovice since February 2020, is part of our long-term plan to reduce emissions.

We continue to advance sustainable technologies. In 2025, we plan to install a photovoltaic power plant on the roofs of our production halls, which will cover approximately 5% of the plant’s energy consumption. Since 2022, we have also been the first plant within Hyundai Motor Group to source electricity exclusively from 100% renewable sources, further emphasizing our commitment to environmentally friendly manufacturing.